Embroidery Digitizing? What does that mean?

Share

Digitizing for Embroidery: Unlocking Creative Potential

Embroidery has long been a cherished form of artistry, transforming plain fabrics into vibrant canvases that tell stories through stitches. Over the years, technology has revolutionized this age-old craft, making it more accessible and versatile than ever before. At the heart of this transformation lies the concept of digitizing for embroidery, a process that has empowered artists and businesses to turn their designs into exquisite embroidered masterpieces. In this blog post, we will explore what digitizing for embroidery means, its significance, and how it has reshaped the world of textile artistry.

What is Digitizing for Embroidery?

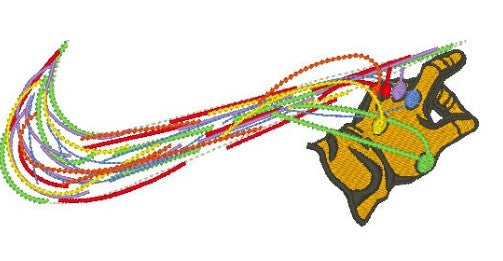

Digitizing for embroidery is the art of converting digital artwork or designs into a format that can be stitched by an embroidery machine. This process involves intricate planning and programming to translate colors, shapes, and textures into a language that embroidery machines understand – a series of commands that dictate the placement and movement of the needle and thread.

Key Steps in the Digitizing Process

1. **Design Input:** The journey begins with a digital design, whether it's a logo, artwork, or a custom pattern created by an artist. This design serves as the blueprint for the embroidery project.

2. **Digitization Software:** Specialized software is used to convert the design into an embroidery-friendly format. The digitizer assigns stitch types, stitch directions, densities, and thread colors to each element of the design.

3. **Stitch File Creation:** The digitization software generates a stitch file (usually in formats like .DST, .PES, or .EXP) that the embroidery machine can read. This file contains instructions for the machine's needle and thread.

4. **Machine Setup:** The embroidery machine is prepared with the appropriate thread colors, the fabric is hooped, and the digitized design is loaded.

5. **Embroidery Process:** The machine executes the design by following the instructions in the stitch file, creating the embroidered pattern on the fabric.

Significance of Digitizing for Embroidery

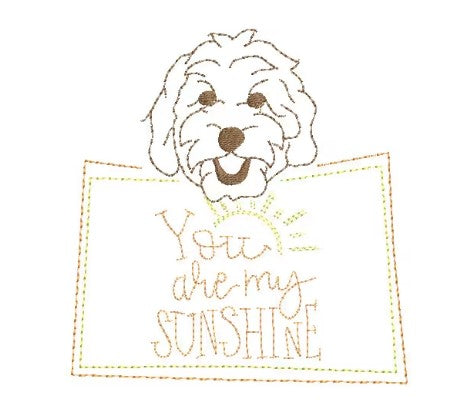

1. **Precision and Consistency:** Digitization allows for unparalleled precision in embroidery. Each stitch is calculated and executed with consistency, ensuring that the final product faithfully represents the original design.

2. **Complexity and Detail:** This process enables the embroidery of intricate details and complex designs that would be challenging or impossible to achieve by hand.

3. **Efficiency:** Digitizing streamlines the embroidery process, reducing production time and costs. It allows for mass production without sacrificing quality.

4. **Customization:** Artists and businesses can bring their unique designs to life on textiles. Customization is key for branding, personalization, and creating one-of-a-kind textile art.

5. **Versatility:** Digitized embroidery can be applied to a wide range of materials, from clothing and accessories to home decor items, expanding the possibilities for textile artistry.

6. **Conservation of Traditional Craft:** While digitization has introduced modern tools, it helps preserve the tradition of embroidery by making it relevant in contemporary contexts.

Digitizing for embroidery represents a fusion of art and technology, opening up new horizons for creative expression. It empowers artists and entrepreneurs to craft exquisite designs with precision, detail, and efficiency. Whether you're a textile artist looking to bring your creations to life or a business seeking to brand your products with unique embroidery, the digitizing process has revolutionized the world of embroidery, making it more accessible and vibrant than ever before. Embrace the digital era and unlock your creative potential through the art of digitizing for embroidery.

Embroidery has long been a cherished form of artistry, transforming plain fabrics into vibrant canvases that tell stories through stitches. Over the years, technology has revolutionized this age-old craft, making it more accessible and versatile than ever before. At the heart of this transformation lies the concept of digitizing for embroidery, a process that has empowered artists and businesses to turn their designs into exquisite embroidered masterpieces. In this blog post, we will explore what digitizing for embroidery means, its significance, and how it has reshaped the world of textile artistry.

What is Digitizing for Embroidery?

Digitizing for embroidery is the art of converting digital artwork or designs into a format that can be stitched by an embroidery machine. This process involves intricate planning and programming to translate colors, shapes, and textures into a language that embroidery machines understand – a series of commands that dictate the placement and movement of the needle and thread.

Key Steps in the Digitizing Process

1. **Design Input:** The journey begins with a digital design, whether it's a logo, artwork, or a custom pattern created by an artist. This design serves as the blueprint for the embroidery project.

2. **Digitization Software:** Specialized software is used to convert the design into an embroidery-friendly format. The digitizer assigns stitch types, stitch directions, densities, and thread colors to each element of the design.

3. **Stitch File Creation:** The digitization software generates a stitch file (usually in formats like .DST, .PES, or .EXP) that the embroidery machine can read. This file contains instructions for the machine's needle and thread.

4. **Machine Setup:** The embroidery machine is prepared with the appropriate thread colors, the fabric is hooped, and the digitized design is loaded.

5. **Embroidery Process:** The machine executes the design by following the instructions in the stitch file, creating the embroidered pattern on the fabric.

Significance of Digitizing for Embroidery

1. **Precision and Consistency:** Digitization allows for unparalleled precision in embroidery. Each stitch is calculated and executed with consistency, ensuring that the final product faithfully represents the original design.

2. **Complexity and Detail:** This process enables the embroidery of intricate details and complex designs that would be challenging or impossible to achieve by hand.

3. **Efficiency:** Digitizing streamlines the embroidery process, reducing production time and costs. It allows for mass production without sacrificing quality.

4. **Customization:** Artists and businesses can bring their unique designs to life on textiles. Customization is key for branding, personalization, and creating one-of-a-kind textile art.

5. **Versatility:** Digitized embroidery can be applied to a wide range of materials, from clothing and accessories to home decor items, expanding the possibilities for textile artistry.

6. **Conservation of Traditional Craft:** While digitization has introduced modern tools, it helps preserve the tradition of embroidery by making it relevant in contemporary contexts.

Digitizing for embroidery represents a fusion of art and technology, opening up new horizons for creative expression. It empowers artists and entrepreneurs to craft exquisite designs with precision, detail, and efficiency. Whether you're a textile artist looking to bring your creations to life or a business seeking to brand your products with unique embroidery, the digitizing process has revolutionized the world of embroidery, making it more accessible and vibrant than ever before. Embrace the digital era and unlock your creative potential through the art of digitizing for embroidery.